Products and double deck screening technology QA442 screening mobile crusher

The working principle of QA442 Screening Mobile Crusher is mainly based on its internal crushing mechanism and screening mechanism. The crushing mechanism is based on the internal crushing mechanism and screening mechanism. The crushing mechanism strikes and squeezes the materials through the high-speed rotating crushing hammer or crushing teeth to achieve the crushing effect. The screening mechanism grades and screens the crushed materials through vibrating screen mesh to obtain products of different particle sizes.QA442 Screening Mobile Crusher adopts advanced crushing technology with high crushing efficiency and large processing capacity. Equipped with high-precision vibrating screen mesh, the equipment can accurately classify and screen the crushed materials to meet the requirements of different particle sizes.QA442 Screening Mobile Crusher adopts tyre-type design, which is convenient and quick to move, and can arrive at the work site quickly. Equipped with intelligent control system, the equipment can realise remote monitoring and automated operation, which improves the operation efficiency and safety.QA442 Screening Mobile Crusher adopts advanced dust removal and noise reduction technology, which reduces dust and noise pollution and meets the requirements of environmental protection. In order to ensure the long-term stable operation of QA442 Screening Mobile Crusher, regular maintenance and repair work is required. This includes checking whether the fasteners of the equipment are loose, whether the lubrication system is good, and whether the transmission parts are worn out. At the same time, it is also necessary to regularly clean the dust and debris on the surface of the equipment to keep it clean and tidy.

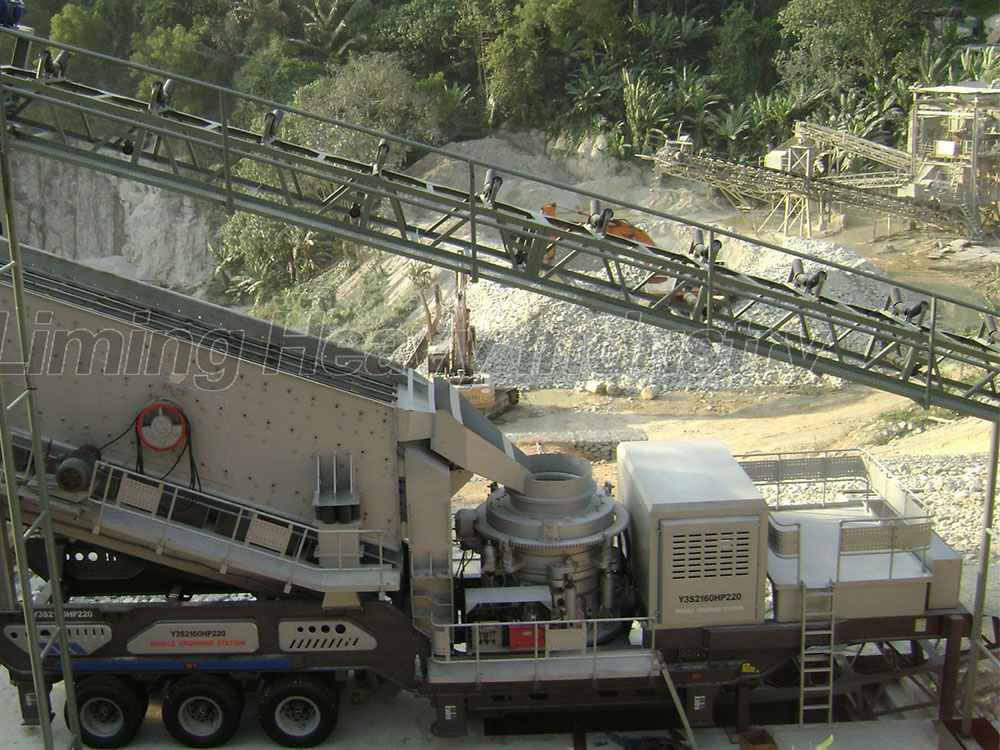

QA442 Screening Mobile Crusher Applications

In the field of mining, QA442 screening mobile crusher plays a vital role. It can efficiently crush and screen all kinds of ores and rocks, providing suitable raw materials for subsequent smelting and processing. Whether it is hard iron ore or brittle quartz stone, QA442 Screening Mobile Crusher can easily cope with it, showing its powerful crushing capacity and accurate screening effect. At the same time, its mobile and convenient characteristics also enable the equipment to quickly reach the mine site and improve the mining efficiency.

With the acceleration of urbanisation, the disposal of construction waste has become an urgent problem, and the QA442 Screening Mobile Crusher also performs well in this field. It is capable of crushing and screening construction waste, converting waste concrete blocks, bricks, etc. into reusable aggregates and sand. These recycled resources can not only be used in the fields of road paving and brick manufacturing, but also as raw materials for concrete and mortar, realising the recycling of resources and reducing the dependence on natural resources and the damage to the environment.

QA442 screening mobile crusher also plays an irreplaceable role in road and railway construction. It can provide high-quality stone and sand to meet the demand of road paving and railway ballast. Meanwhile, its efficient crushing and screening capacity ensures the smooth progress of the project and improves the construction efficiency and quality. In addition, the mobility of QA442 screening mobile crusher also gives it more advantages in complex construction environments, and it can quickly adapt to different construction sites and conditions.

QA442 Screening Mobile Crusher Advantages

Highly efficient crushing and screening capacity

QA442 Screening Mobile Crusher is equipped with advanced crushing mechanism and screening mechanism, which can efficiently crush and screen various materials. The crushing mechanism strikes and squeezes the materials through the high-speed rotating crushing hammer or crushing teeth to achieve efficient crushing effect; while the screening mechanism grades and screens the crushed materials through the vibrating screen mesh to ensure that different particle sizes of products are obtained. This efficient crushing and screening capacity greatly improves the production efficiency and reduces the production cost.

Convenient and Adaptable

The QA442 screening mobile crusher adopts a tyre-type design, which is convenient and quick to move and can reach the work site quickly. This design not only improves the flexibility of the equipment, but also enables it to adapt to various complex construction environments. Whether it is a rugged mountain road or a narrow construction site, QA442 Screening Mobile Crusher can easily cope with it and ensure the smooth progress of construction. At the same time, its strong adaptability also makes the equipment can be widely used in mining, construction, highway, railway and other fields.

Intelligent control and easy operation

QA442 screening mobile crusher is equipped with intelligent control system, which can realise remote monitoring and automatic operation. Through the touch screen or remote start and other operating interfaces, the operator can easily control the operating status of the equipment to achieve accurate crushing and screening results. This intelligent control not only improves the operation simplicity of the equipment, but also reduces the labour intensity of the operators and improves the working efficiency.

Environmental protection, energy saving and low maintenance cost

QA442 Screening Mobile Crusher takes the requirements of environmental protection and energy saving into full consideration during the design and manufacturing process. The equipment adopts advanced dust removal and noise reduction technology, which effectively reduces the pollution of dust and noise and meets the requirements of environmental protection. Meanwhile, its optimised structure and advanced material selection make the equipment consume less energy and have lower maintenance costs during operation. This environmentally friendly and energy-saving feature makes QA442 screening mobile crusher more competitive in the market.

Durable, Reliable and Long Service Life

QA442 Screening Mobile Crusher adopts high-quality materials and advanced manufacturing process to ensure the durability and reliability of the equipment. All components of the equipment have been strictly tested and screened to ensure that they can still maintain good performance under harsh working environments. In addition, the equipment is equipped with a perfect maintenance system, which can detect and deal with potential faults in time and prolong the service life of the equipment.

QA442 Screening Mobile Crusher Working Principle

The work of the QA442 Screening Mobile Crusher starts with the feeding of the material. Through the feeding system, the materials are evenly fed into the crushing chamber. The feeding system plays a key role in this process, which ensures that the material can enter the crushing chamber continuously and stably, providing a strong guarantee for the subsequent crushing operation.

After entering the crushing chamber, the material ushers in the real crushing challenge.QA442 Screening Mobile Crusher adopts the advanced cone crushing mechanism, which carries out strong squeezing, impacting and shearing effects on the material through the relative motion between the high-speed rotating crushing wall and the fixed molar wall. During this process, the material is gradually crushed into smaller particles until it reaches the predetermined particle size requirement.

The design of the cone crushing mechanism cleverly utilises the principle of laminar crushing, i.e. the material is subjected to multi-level extrusion and crushing in the crushing chamber, thus realising high efficiency and energy-saving crushing effect. Meanwhile, the surfaces of the crushing wall and rolling wall are made of wear-resistant materials, ensuring the long-term stable operation and wear-resistant performance of the equipment.

The crushed material then enters the screening system.The QA442 Screening Mobile Crusher is equipped with a high-precision vibrating screen mesh, which is capable of accurately grading the material according to the preset particle size requirements. Under the action of the vibrating screen mesh, the materials are constantly thrown up and down, achieving effective separation between particles. Finished materials that meet the particle size requirements are discharged through the outlet below the screen, while materials that do not meet the requirements are returned to the crushing chamber for re-crushing.

The vibration source of the screening system usually adopts vibration exciter or vibration motor, which can produce stable vibration frequency and amplitude to ensure the continuity and stability of the screening process. At the same time, the screening system is also equipped with adjustable screen angle and amplitude adjustment devices, so as to adjust and optimise according to the characteristics and particle size requirements of different materials.

In the working process of QA442 screening mobile crusher, it is also equipped with perfect lubrication system and cooling system. The lubrication system ensures good lubrication and reduces wear and tear between the various parts of the equipment, prolonging the service life of the equipment. The cooling system, on the other hand, effectively reduces the temperature of the equipment in the working process through circulating cooling water or air cooling, ensuring the normal operation and stability of the equipment.

QA442 Screening Mobile Crusher Technical Parameters

| Screen size | 6 x 1.5 m | Capacity | 600 tph |

| length | 18.3 m | width | 3.0 m |

| height | 3.6 m | Weight | 33,000 kg |