CS430 stationary cone crusher with better crushing effect

CS430 Cone Crusher is widely used in metallurgy, construction, chemical industry, transport and other fields due to its simple structure, reliable performance, convenient operation and easy maintenance. This crusher is especially suitable for crushing medium hardness materials, including but not limited to all kinds of ores, slag and construction waste. The feed opening is designed in two sizes, the large feed opening ranges from 360mm (EC chamber) to 235mm (MC chamber), while the small feed opening is correspondingly smaller, which ensures that all kinds of materials can enter the crushing chamber smoothly for processing. The size of the discharge opening is also carefully designed, with the EC chamber type generally controlled between 19-51mm, while other chamber types vary according to demand, to meet the crushing task of different particle size requirements. In terms of capacity, the CS430 Cone Crusher performs well, with a production capacity ranging from 91 tonnes to 344 tonnes, and is able to work consistently and stably for more than 20 hours, fully meeting the needs of efficient production.

CS430 stationary cone crusher with better crushing effect Applications

In the field of mining development, the CS430 stationary cone crusher, with its excellent crushing performance and stable operational performance, has become the ideal choice for processing various metal ores. Whether it is hard iron ore or non-ferrous metal ores containing impurities, CS430 can effectively refine and crush the ores through its efficient crushing mechanism, providing high-quality raw materials for the subsequent beneficiation process. This not only improves the efficiency of beneficiation, but also significantly increases the utilisation rate and economic benefits of the ore.

In the field of non-metallic materials, CS430 stationary cone crusher also plays an important role. The mining and processing of many non-metallic minerals requires fine handling and splitting, and the CS430 cone crusher can easily meet this challenge by meticulously crushing soft or hard non-metallic minerals such as limestone, gypsum, etc., to meet different process requirements. This fine processing capability makes the CS430 very promising for application in the field of non-metallic materials.

The CS430 stationary cone crusher is also an indispensable equipment in the preparation of construction materials. It can efficiently process sand and gravel materials, cement clinker, etc., and produce materials such as sand aggregate and crushed stone for construction that meet standard specifications. These high-quality construction materials not only improve the overall quality of construction projects, but also provide strong support for building construction. In addition, the CS430 Cone Crusher's highly efficient processing capacity helps to reduce the production cost of construction materials and improve economic efficiency.

In the coal and metallurgical industries, CS430 stationary cone crusher also plays an important role. When processing coke, the machine is able to meticulously separate and process the barren gas from blast furnace gas recovery, providing high-quality raw materials for the subsequent metallurgical process. In the metallurgical industry, the CS430 can be used in the preparation of raw materials in the iron and steel smelting process, and through its efficient crushing mechanism, it can refine and homogenise the raw materials, thus improving the production efficiency and quality of steel.

CS430 stationary cone crusher with better crushing effect Advantages

Stable and reliable performance

Stability is one of the highlights of the CS430 stationary cone crusher. The machine is made of high-quality materials and superb manufacturing process to ensure the robustness and durability of its structure. Even under prolonged, high-intensity operating conditions, the CS430 maintains stable performance and reduces breakdowns and downtime, thus increasing the reliability and service life of the plant.

Flexible Adaptability

The CS430 stationary cone crusher has excellent adaptability and is capable of handling a wide range of material types, including hard rock, soft rock, ores, construction waste and more. By adjusting the crushing chamber type and discharge opening size, it can be easily adapted to different crushing needs and particle size requirements. This flexibility allows the CS430 to deliver optimal performance in a variety of application scenarios.

Intelligent Operation and Maintenance

With the development of intelligent technology, the CS430 stationary cone crusher also incorporates intelligent elements. Equipped with advanced control systems and monitoring devices, the machine is able to monitor the operating status and performance parameters in real time, providing operators with accurate data feedback. This not only improves the convenience and accuracy of operation, but also helps to detect and deal with potential problems in time and reduce maintenance costs.

Environmental protection and energy saving

Environmental protection and energy saving are important trends in current social development, and the CS430 Stationary Cone Crusher excels in this regard. Its highly efficient crushing mechanism and optimised design make it possible to effectively control the noise, dust, vibration and other pollutants generated during operation. Meanwhile, through rational energy management and the application of energy-saving technologies, the CS430 ensures crushing efficiency while reducing energy consumption and carbon emissions, in line with the concept of green and sustainable development.

Easy maintenance and upgrading

The CS430 stationary cone crusher is designed with easy maintenance and upgrading in mind. Its simple and straightforward structure makes it easy for operators to carry out routine maintenance and repair work. It also supports modular design and upgrades, allowing for flexible expansion and modification to meet changing production requirements.

Highly efficient crushing capacity

The CS430 stationary cone crusher adopts advanced crushing technology and design to ensure its excellent crushing capacity. Its unique crushing chamber and optimised crushing mechanism enable the materials to be evenly and powerfully crushed and ground during the crushing process, thus achieving high efficiency and fast crushing effect. This efficient crushing capacity not only improves production efficiency, but also reduces energy consumption and operating costs.

CS430 stationary cone crusher with better crushing effect Working Principle

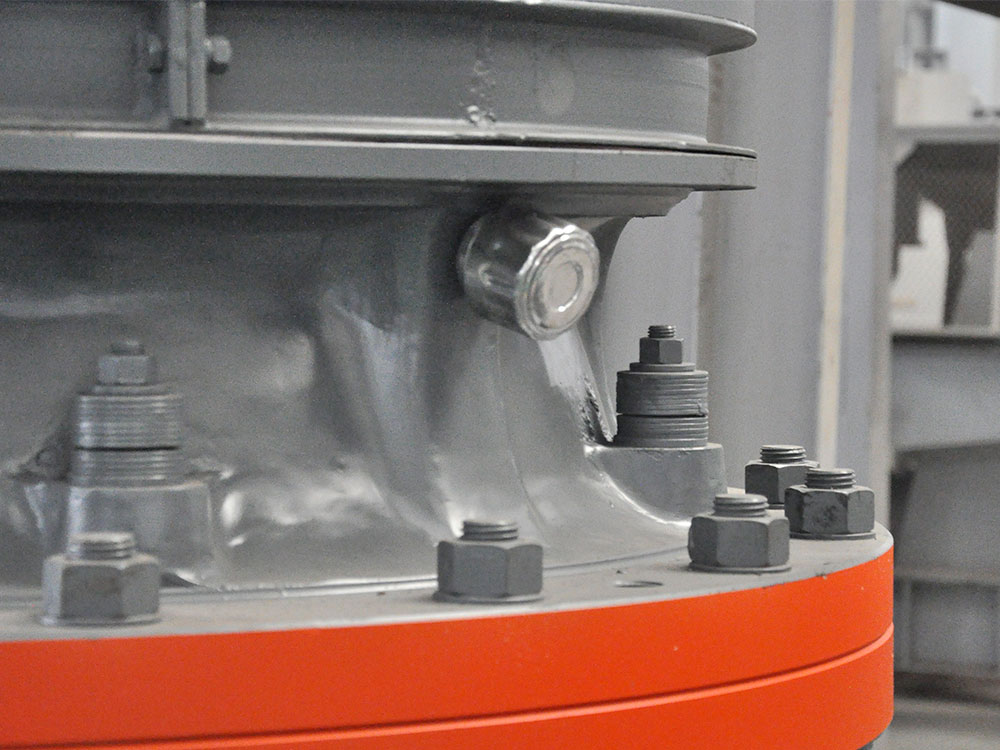

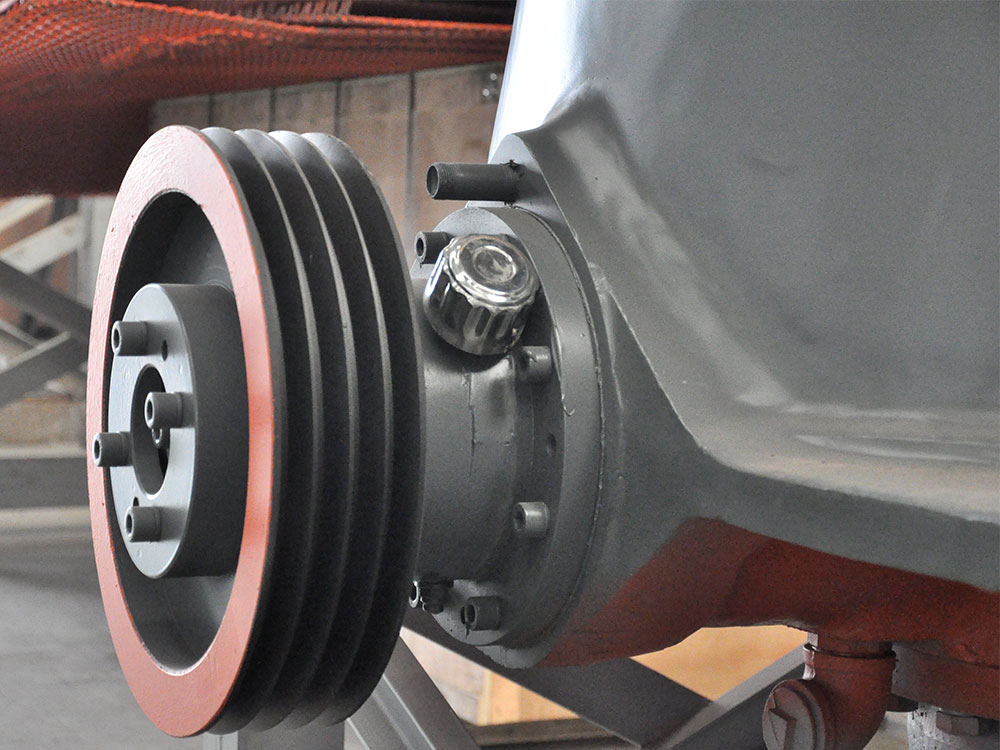

Material enters the crushing chamber through the feed opening. The feed opening is usually located at the top of the crushing chamber and is supplied with material through a device such as a feed hopper or vibrating feeder. When the motor is started, it drives the drive shaft to rotate through the pulley or coupling. The drive shaft then drives the eccentric sleeve to rotate, so that the axis of the crushing cone is forced by the eccentric sleeve to rotate and oscillate. This movement makes the crushing wall of the crushing cone close to and away from the surface of the mortar wall which is solidly mounted on the adjusting sleeve. In this process, the material in the crushing cavity by the cone and wall compression, impact and bending effect, so as to achieve crushing. After crushing, the material is discharged through the outlet at the bottom of the crushing chamber. The design of the discharge opening is also crucial, which not only concerns the crushing efficiency, but also directly affects the particle size of the finished product. Therefore, the size of the discharge opening can usually be adjusted according to the actual demand, in order to meet the production needs of different particle size requirements. By precisely controlling the opening of the discharge opening, the particle size of the material can be accurately controlled, thus ensuring the stability and consistency of product quality.

CS430 stationary cone crusher with better crushing effect Technical Parameters

| feed size | 400 mm | Power | 132 kW |

| Closed side setting range | 24 - 54 mm | Weight | 13,098 kg |

| range | 16 - 30 mm | Capacity | 90-350 t/h |