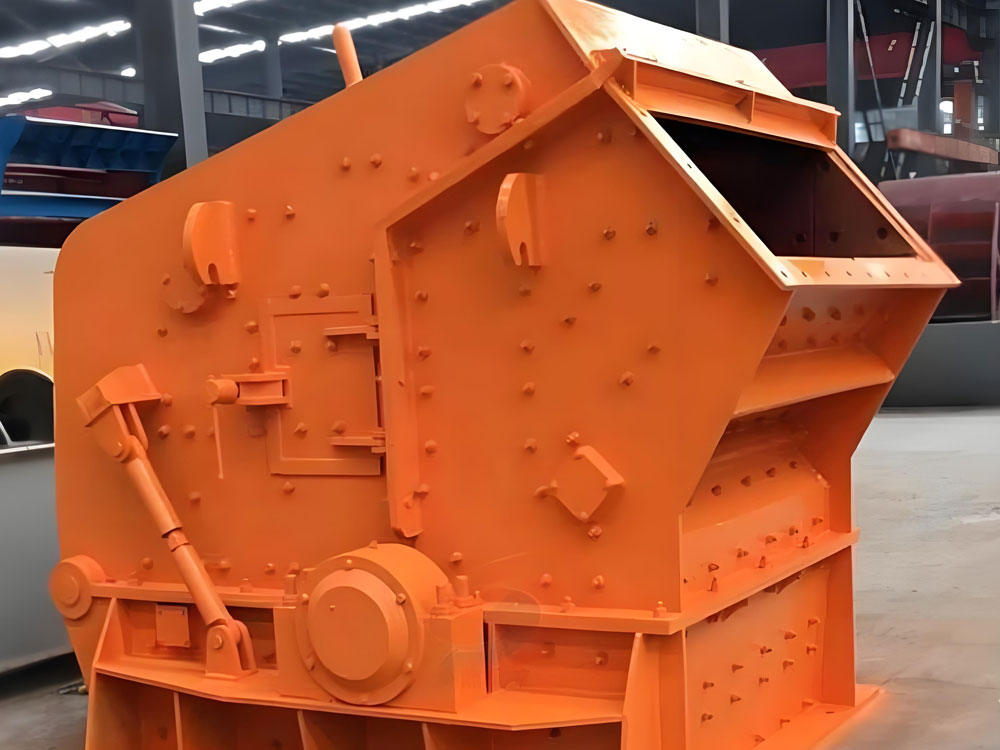

PF impact crusher: a reliable choice for efficient crushing

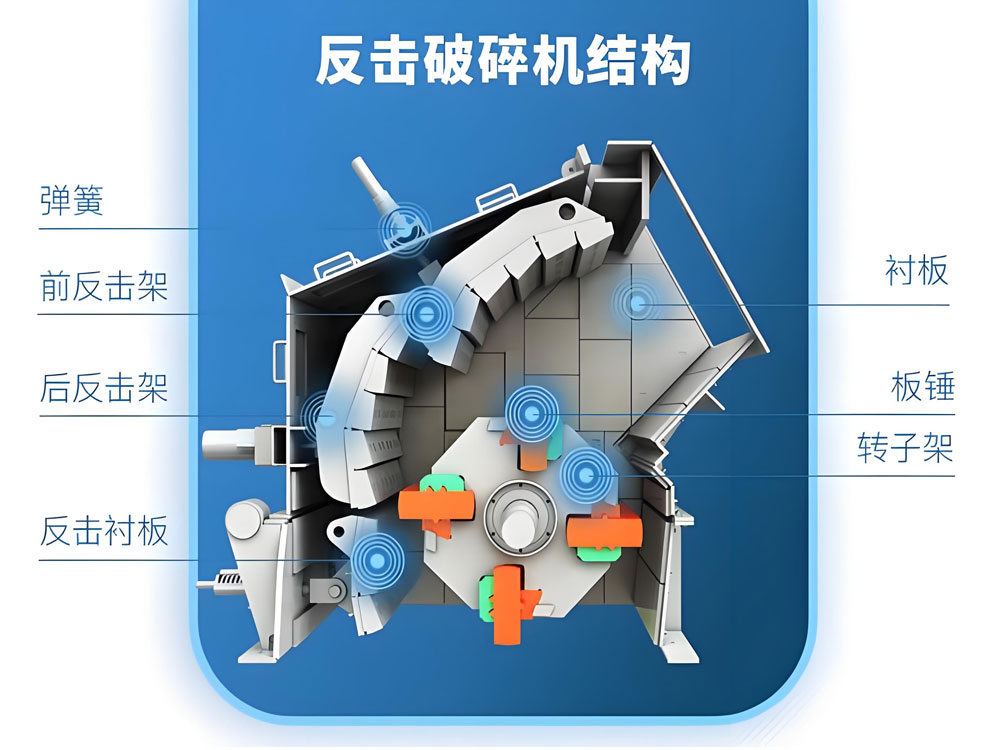

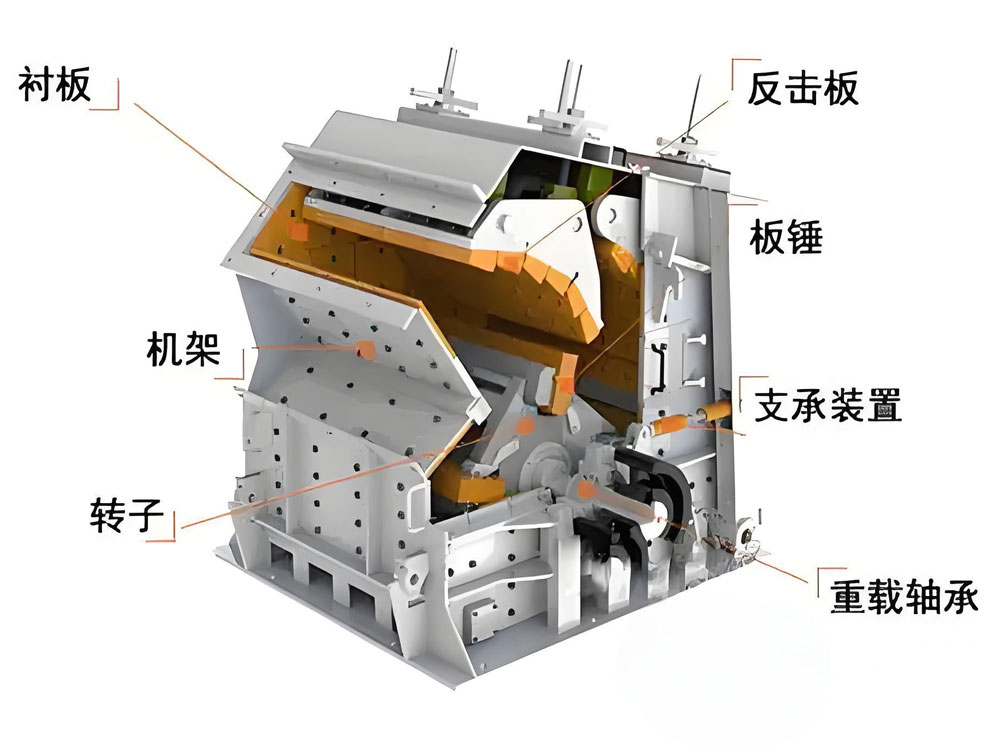

The impact crusher is a crushing equipment with simple structure and high efficiency and energy saving. Its working principle is to crush the material by high-speed rotating rotor and plate hammer. The material collides and strikes multiple times in the crushing chamber, and finally reaches the required particle size. The equipment can adjust the discharge particle size according to different production needs by adjusting the gap between the impact frame and the rotor speed. The discharge particle size of the impact crusher is uniform and in the form of cubic particles, which is suitable for materials with medium hardness, such as limestone, granite, etc. In addition, it has low maintenance cost and convenient replacement of wearing parts, which is suitable for large-scale industrial production.

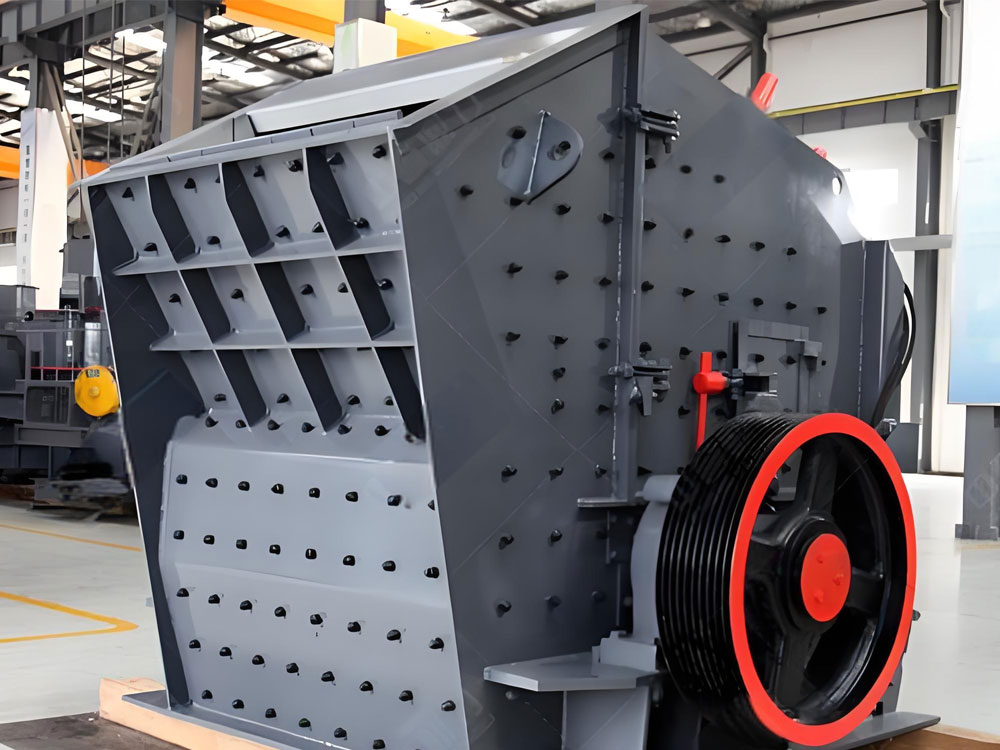

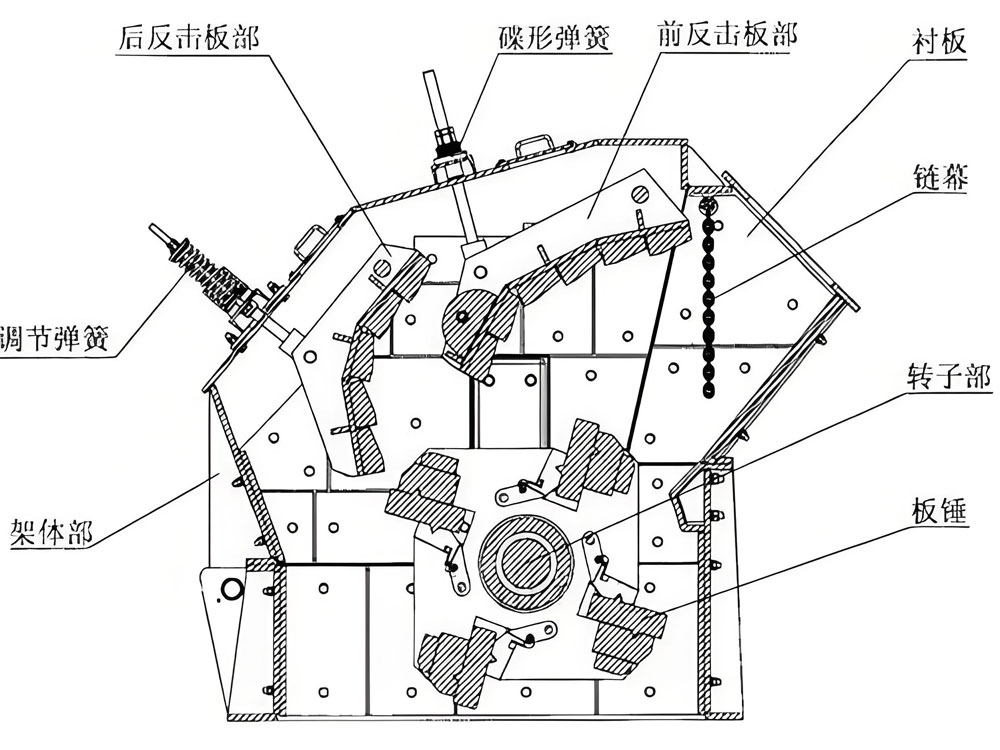

PF impact crusher Working Principle

The working principle of the impact crusher is to use impact energy to crush materials. During the working process, the motor drives the rotor to rotate at high speed. After the material enters the plate hammer action area, it collides with the plate hammer on the rotor and is crushed. The crushed material is thrown to the impact plate, and is impacted and crushed again, and then rebounds from the impact plate to the plate hammer action area, and the above process is repeated. By adjusting the gap between the impact plate and the plate hammer, the size of the output particle size can be controlled. This "stone-beating-iron" crushing method not only has a large crushing ratio, but also has low unit energy consumption, which can meet the process requirements of "more crushing and less grinding".

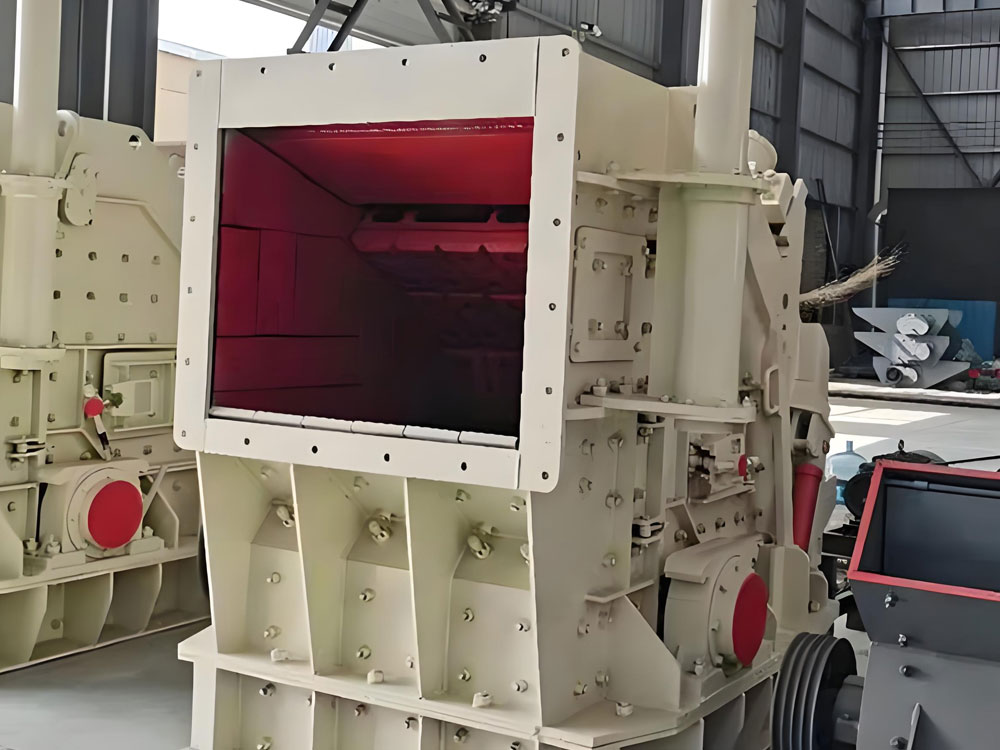

PF impact crusher Advantages

High efficiency and energy saving, large processing capacity

PF1315 impact crusher adopts advanced crushing principle, and the material hits repeatedly between the plate hammer and the impact plate to achieve efficient crushing. Its rotor is reasonably designed, with high speed, large kinetic energy and large crushing ratio. It can crush large pieces of material to the required particle size at one time, significantly improving production efficiency. At the same time, the equipment has low energy consumption and economical operation cost.

Excellent finished particle shape and low needle-like content

PF1315 impact crusher adopts a unique crushing chamber design and three-chamber crushing structure. The material is hit and ground multiple times in the crushing chamber. The finished particle shape is cubic, with low needle-like content, uniform particle size and excellent quality. It can be directly used for high-standard concrete aggregate production to meet various engineering needs.

Easy operation and maintenance, stable and reliable operation

PF1315 impact crusher has a reasonable structural design, and key components are made of high-quality wear-resistant materials, with a long service life and stable and reliable operation. The equipment has a high degree of automation, easy operation, and convenient maintenance, which can effectively reduce labor costs and maintenance costs.

Strong adaptability and wide application range

PF1315 impact crusher can crush various ores and rocks with a compressive strength not exceeding 350MPa, such as limestone, granite, basalt, river pebbles, etc. Its feed particle size is large and the discharge particle size is adjustable, which can meet the production needs of different users and is widely used in mining, building materials, chemical industry, metallurgy and other industries.

Excellent environmental protection performance, low noise and less dust

PF1315 impact crusher adopts advanced sealing structure and dust removal device, which effectively reduces the noise and dust pollution during the operation of the equipment, improves the working environment, and meets the national environmental protection requirements.

PF impact crusher Technical Parameters

| Rotor size | 1300mm×1500mm | Processing capacity | 130-250t/h |

| Feed port size | 860mm×1520mm | Motor power | 200-250kW |

| Maximum feed size | ≤500mm | Equipment weight | 18.6t |

PF impact crusher Construction waste recycling project

Equipment model: PF1315 impact crusher

Supporting equipment: mobile feeder, mobile screening station

Application field: construction waste treatment and recycling

Customer background: A city construction waste treatment plant processes about 1,000 tons of construction waste per day. The goal is to crush the construction waste and convert it into recycled aggregate for road base and concrete mixing station.

Project requirements: The customer needs a crushing equipment that can handle construction waste (including concrete blocks, bricks and tiles, etc.), requiring the finished product size to be between 5-30mm, and the equipment needs to have high flexibility and be easy to move and transfer.

Solution--

Equipment selection: The PF1315 impact crusher was selected. The feed port size of the equipment is 1300×1500mm, the maximum feed particle size is 400mm, and the processing capacity can reach 200 tons/hour.

Process flow: Construction waste is fed into the impact crusher by a mobile feeder. The crushed materials are graded by a mobile screening station. The recycled aggregates with qualified particle size are used for road base and concrete mixing station, and the unqualified materials are returned to the crusher for re-crushing.

Operation effect: The equipment operates stably, and the particle size of the recycled aggregates after crushing is uniform, which fully meets the requirements of road base and concrete mixing station. Customer feedback shows that the equipment is highly flexible, easy to move, and can quickly adapt to different work sites.

Customer evaluation--

Project manager: "PF1315 impact crusher is very suitable for our construction waste treatment project. The equipment is highly flexible, easy to move, and can be quickly transferred. The quality of the recycled aggregates after crushing is very high, which fully meets our requirements. Most importantly, the equipment has low operating costs and simple maintenance."