Jaw Crusher

In recent years, our factory in order to meet the metallurgy, mining, construction and other industrial sectors crushing high strength, high hardness needs, the internal structure of the jaw crusher has been improved many times, so that the performance of the equipment has been greatly improved, not only better efficiency, finished product size is more uniform, easier and faster maintenance, and both energy saving, environmental protection effect, once put into operation, it is welcomed by the majority of users.

In addition, it has launched a new model of mobile jaw crusher, which is more convenient for transferring, no need to hit the foundation fixed, omitting the link of carrying materials, the whole machine with stopping, immediate evacuation of the transfer, very convenient.

Jaw Crusher Application Field

Jaw crusher is widely used in mining, building materials, chemical industry, metallurgy and other industries, and can be used for coarse and medium crushing of all kinds of ores, rocks and other materials whose compressive strength is not greater than 320MPa.

Jaw Crusher Performance Advantages

Advanced components and excellent manufacture

The movable jaw is made of good material, which is durable. The jaw assembly is made of high quality cast steel parts and is driven by two large cast steel flywheels. In addition, the heavy eccentric shaft is made of forged billet, which makes the CJ series jaw crusher work more reliably.

Reliable fit and high strength

The bearing housing adopts integral cast steel structure. The integral cast steel bearing housing ensures a perfect fit with the crusher frame, and also greatly enhances the radial strength of the bearing housing, which is not the case with the split bearing housing. Adopting finite element analysis technology, the crusher has higher strength.

Simple, safe and quick operation

The crushing chamber adopts a symmetrical "V" shape structure, which makes the actual width of the feed opening consistent with the nominal width of the feed opening. The discharge opening can be adjusted quickly and conveniently. The European-style jaw crusher is equipped with a wedge discharge opening adjustment device, which is simpler, safer and faster than the old-fashioned gasket adjustment.

Long life and high production

Larger bearing size and higher load capacity. All CJ series jaw crushers are equipped with larger and more durable eccentric shaft bearings than other crushers of the same specification, whose higher bearing capacity and effective labyrinth seals greatly extend the service life of the bearings. In addition, the machine also adopts toothed guard plate, which increases the effective length of the jaw plate, resulting in higher output.

Different models of jaw crusher

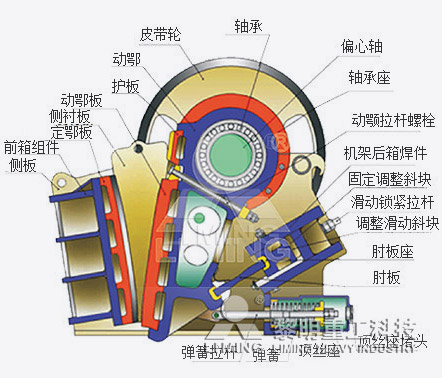

Working Principle

When the jaw crusher works, the motor drives the pulley to drive the eccentric shaft to rotate, so that the movable jaw periodically close to and away from the static jaw, thus causing multiple crushing of materials entering the crushing chamber, such as extrusion, rubbing, grinding, etc., so that the materials to be crushed by the large particle size into a small particle size, and gradually fall until the particle size reaches the requirements of the crusher.

Working Principle of Jaw Crusher

Jaw crusher is mainly composed of static jaw plate, movable jaw plate, frame, upper and lower guards, adjusting seat, movable jaw pull rod and so on.

Jaw Crusher Price Analysis

There are many types of jaw crusher, such as: ordinary type, hydraulic type, German version, movable type, etc. Different types of jaw crusher, the price is not the same. Generally speaking, the ordinary version of the investment savings, hydraulic, German version of the jaw crusher investment is a little more expensive, but easy to use and maintain, energy saving and reduce consumption and environmental benefits, you can according to the actual production situation for the selection.