In-depth analysis of the working principle and advantages of CI721 impact crusher

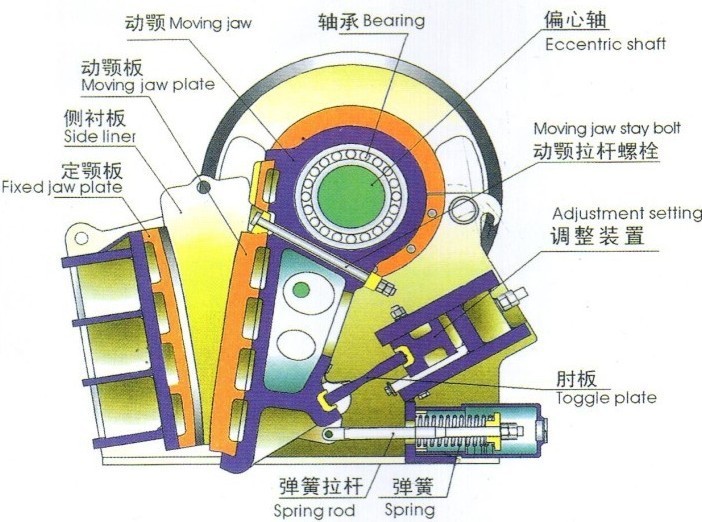

CI721 Stationary Horizontal Shaft Impact Crusher is mainly used for primary crushing of non-abrasive rocks, and is widely used in all kinds of crushing operations, capable of handling a wide range of materials including reinforced concrete. Its unique working principle can induce the material to split along the natural joint surface, thus producing excellent, stress-free cubic products.CI721 Impact Crusher has excellent crushing capacity, and can easily cope with all kinds of hardness of materials, achieving high crushing ratio. The equipment adopts advanced manufacturing technology and optimised structural design to improve energy efficiency and reduce energy consumption. The equipment is equipped with an overload protection device, which can automatically stop the machine in case of overload and protect the equipment from damage. The gap of the impact plate and the opening and closing of the shell can be adjusted hydraulically, which is easy to operate and safe to maintain.CI721 impact crusher has reasonable structural design, easy replacement of wearing parts and low maintenance cost. Output 1 type of aggregate: the granularity of 0-40 mm aggregate, suitable for a variety of construction projects. Railway ballast: ballast with particle size of 40-70mm, meeting the demand of railway construction. Construction waste recycling: crushing reinforced concrete and asphalt concrete, realising the recycling of construction waste.

CI721 impact crusher Applications

In the mining process, CI721 impact crusher plays a vital role. It is capable of crushing the ore into smaller particle size for subsequent beneficiation, smelting and other processes. Whether it is hard iron ore, copper ore, or relatively soft limestone, CI721 Impact Crusher can cope with it. Its advanced crushing technology and efficient crushing capacity enable mining enterprises to mine and utilise mineral resources more efficiently.

Construction industry is another important application field of CI721 impact crusher. In the construction field, the crusher is mainly used to process materials such as construction waste and waste concrete. Through the crushing process, these waste materials can be transformed into recycled aggregates, which can be used to produce new building materials and realise the recycling of resources. In addition, CI721 Impact Crusher can also produce excellent, stress-free cubic products, which are suitable for roadbed filling and other processes in highway and railway construction, providing high-quality fillers for infrastructure construction.

CI721 impact crusher also plays an important role in the construction of highways, railways and other infrastructure. It can crush the large stone materials into the required size, providing high quality crushed materials for the processes of roadbed filling, tunnel excavation and slag disposal. This not only improves the construction efficiency, but also ensures the quality of the project.

Water conservancy and chemical industries are also one of the important application fields of CI721 impact crusher. In water conservancy projects, a large amount of rock waste will be produced during the construction and maintenance of dams, and the CI721 impact crusher can effectively crush these wastes and provide the required raw materials and fillers for the construction of the project. In the chemical industry, the crusher is used for the crushing of various chemical raw materials, such as ammonium sulphate, potassium chloride, etc., to meet the needs of chemical production.

CI721 impact crusher Advantages

Excellent particle shape and crushing ratio

The impact crusher crushes products in cubic shape, with excellent particle shape and low content of fine powder and dust. This excellent particle shape not only improves the quality of the product, but also reduces the dust pollution in the subsequent processing. In addition, the impact crusher has a unique crushing ratio of up to 40, which makes it possible to simplify the material that originally requires three stages of crushing into two or one, greatly reducing the crushing cost of the mineral processing plant.

Intelligence and Reliability

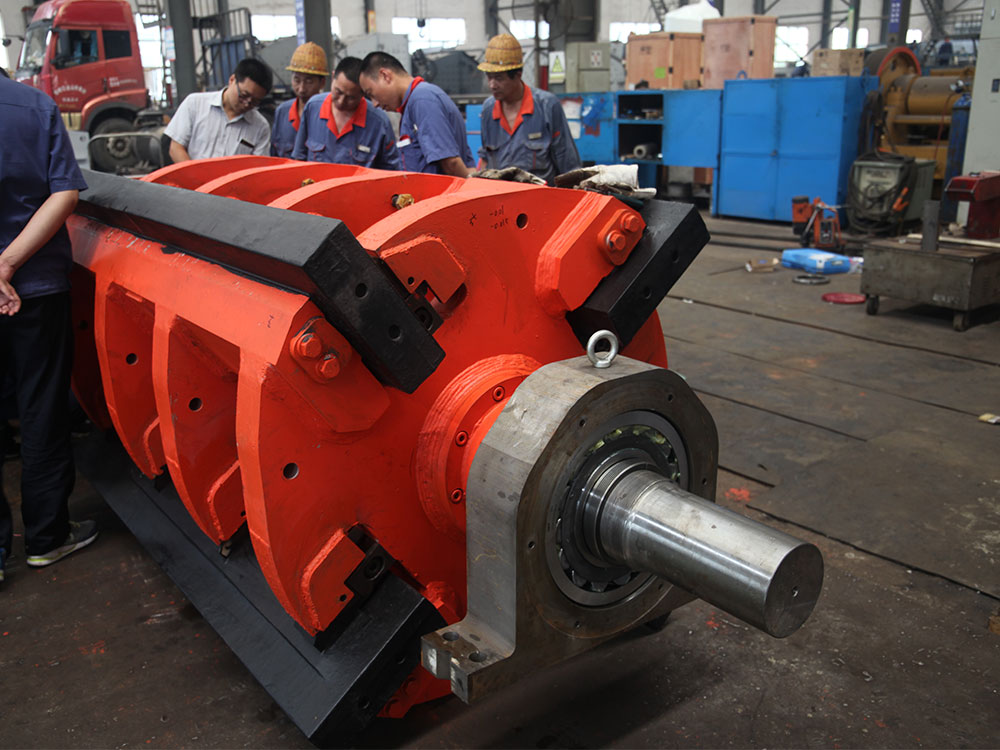

The CI721 impact crusher incorporates advanced software such as SOLIDWORKS, PROE and other measurement and calculation co-design system software and simulation test system to ensure the accuracy and reliability of the equipment design. At the same time, the equipment adopts higher specification rolling bearings with higher bearing capacity to ensure the smooth operation of the equipment. In the manufacturing process, strict testing methods ensure the quality of every detail, so that the equipment in long-term operation to maintain high efficiency and stability.

Reduce noise and dust pollution

During the crushing process, CI721 impact crusher produces less noise and dust, which is friendly to the environment. This not only helps to improve the working environment, productivity and quality, but also meets the current social requirements for environmental protection and sustainable development.

Efficient production and particle size control

The CI721 Impact Crusher has a highly efficient production capacity. Its unique crushing principle allows the material to be subjected to multiple impacts and bounces inside the crushing chamber, thus quickly crushing the material to the required size. This efficient crushing method not only improves production efficiency, but also significantly reduces energy consumption. Meanwhile, by adjusting the gap between the impact plate and the hammer, the granularity of the material can be easily controlled to meet different production requirements. This flexibility in size control makes the CI721 Impact Crusher an excellent performer in production scenarios where precise size distribution is required.

CI721 impact crusher Working Principle

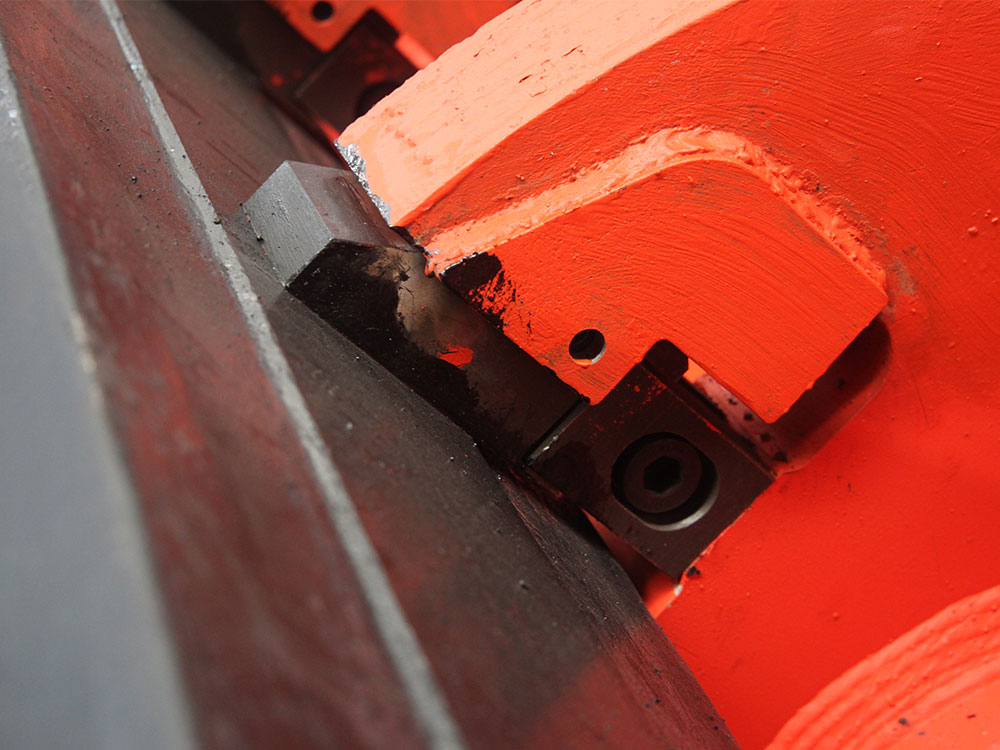

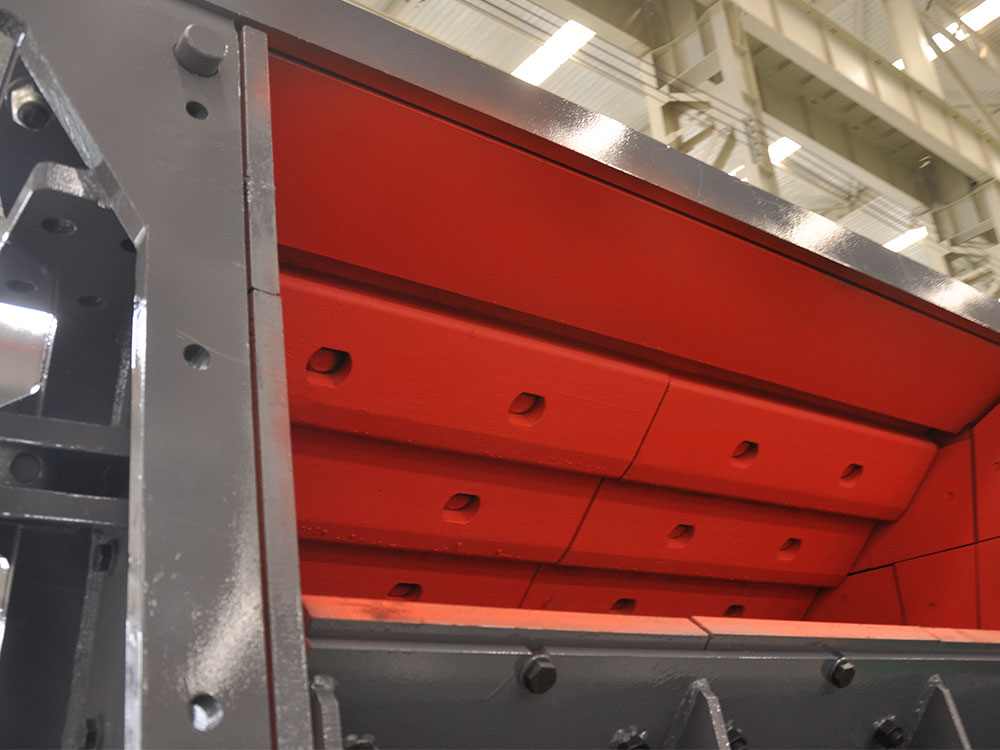

CI721 Impact Crusher is a kind of heavy machinery and equipment that uses impact energy to crush materials, and its working principle is mainly based on the interaction between materials and tools. With its high efficiency, reliability and adaptability, this kind of crusher is widely used in many industries, such as mining, construction, highway, railway and so on. The material first enters the crushing chamber through the feed opening. The design of the feed opening ensures that the material can enter the crushing chamber smoothly, and at the same time avoids material clogging. After entering the crushing chamber, the material is impacted by the high-speed rotating hammers. The plate hammer is connected to the motor through the rotor and rotates at a high speed to produce a huge impact force. This impact force causes the material to be quickly crushed into smaller pieces. The material crushed by the plate hammer is thrown to the impact plate installed on the top of the rotor. The design of the impact plate enables it to effectively rebound the material, so that it will be impacted again. This repeated impact process makes the material continuously crushed until it reaches the required particle size. The materials are not only directly impacted by the hammers and impact plates, but also hit each other in the crushing chamber. This multiple crushing process ensures that the material is evenly crushed to the required size. Once the materials have been crushed to the required size, they are forced out in the gap between the hammers and the impact plates and become the crushed product. These products can be further processed by conveying equipment or used in other production stages.

CI721 impact crusher Technical Parameters

| feed size | 900 mm | Weight | 16,000 kg |

| power | 250 kW | Length | 3.12 m |

| Width | 2.37 m | Height | 2.51 m |