CV228 crusher is the first choice for high efficiency and low energy consumption.

CV228 impact crusher adopts the principle of stone hitting stone for crushing operation. During the free fall, the stones will collide violently with the stones thrown out after being accelerated by the impeller, thus realising the crushing effect. This crushing mechanism not only significantly improves the crushing efficiency, but also effectively reduces the wear and tear of the machine and the level of energy consumption.CV228 not only has the dual function of fine crushing and coarse grinding, but also has a very high crushing efficiency, and can easily cope with a variety of soft and hard rock processing needs. The machine has a novel and unique structural design, smooth and reliable operation, easy and quick installation and maintenance, and relatively low operating costs. The crushed product has full and rounded particles, adjustable particle size distribution and controllable stone powder content, making it an ideal choice for construction sand and highway aggregate. In addition, the equipment is carefully optimised for energy saving, low carbon and environmental protection, which is fully in line with the development trend of modern industry. For a small number of easy-to-wear parts, CV228 adopts extra hard wear-resistant material, which is compact, lightweight and easy to replace, thus effectively extending the service life of the equipment. Therefore, the CV228 impact crusher is widely used in artificial sand making, construction aggregate production and fine crushing and coarse grinding of metallurgical slag in many fields, such as metal and non-metallic ores, cement, refractory materials, abrasive materials, construction aggregates, artificial sand making and ore tailings, etc. The CV228 impact crusher is also widely used for the fine crushing and coarse grinding of medium-hard, extra-hard, and hard crusher, which is very easy to replace. Especially for medium-hard, extra-hard and abrasive materials, such as silicon carbide, adamantine, sintered alumina-vanadium, magnesia, etc., CV228 shows more excellent performance than other types of crushers.

CV228 crusher is the first choice for high efficiency and low energy consumption Applications

In the mining industry, CV228 impact crusher is the preferred equipment for stone processing and ore crushing. It is capable of handling ores of various hardnesses, including iron ore, non-ferrous metal ores, granite, limestone, quartzite and so on. Its powerful crushing capacity and stable performance make it play an important role in mining, ore dressing and metallurgy.CV228 impact crusher not only improves the crushing efficiency of the ore, but also ensures that the particle size of the crushed product is uniform, which provides a good raw material base for the subsequent beneficiation and smelting process.

In the construction industry, CV228 impact crusher also plays an important role. It is widely used to crush materials such as concrete, cement and bricks, providing strong support for the production of sand and gravel aggregates at construction sites. In addition, it can also produce high-quality artificial sand, which is suitable for road and bridge construction, high-rise buildings, municipal engineering, etc. The high efficiency and energy-saving features of the CV228 Impact Crusher have made it highly favoured in the construction industry.

In the renewable resources industry, CV228 Impact Crusher is used to crush all kinds of materials, such as concrete, glass, slag and so on. After crushing, these materials can be reused as renewable resources, which helps to reduce resource waste and environmental pollution.The high efficiency and energy-saving features of CV228 Impact Crusher make it have a broad application prospect in the renewable resources industry.

In the water conservancy industry, CV228 Impact Crusher is used in the production of Rolled Concrete (RCC) in dam construction projects.RCC is a high-performance concrete material with high strength, high durability, and good impermeability.CV228 Impact Crusher is able to produce aggregate that meets the requirements of RCC production, which provides high-quality material support for dam construction projects.

CV228 crusher is the first choice for high efficiency and low energy consumption Advantages

Widely adaptable, capable of handling a wide range of materials

The CV228 impact crusher has a wide range of adaptability and is capable of handling a wide range of material types, including hard and brittle materials, medium-hard materials, and super-hard materials. Whether it's metal ores, non-metallic ores or cement, this equipment can handle it with ease. This wide adaptability makes the CV228 impact crusher widely used in many industries.

Large crushing ratio and uniform product size

The CV228 Impact Crusher has a large crushing ratio and is capable of crushing materials into various required particle sizes. Its unique crushing chamber structure and optimised rotor design make the materials subjected to multiple impacts, friction and grinding in the crushing chamber, thus obtaining crushed products with uniform particle size and regular shape. This is undoubtedly a great advantage for industries that require strict control of product particle size.

Environmental protection and energy saving, in line with green production requirements

CV228 impact crusher produces low dust and noise during the crushing process, which meets the requirements of environmental protection and energy saving. At the same time, the equipment can also effectively reduce metal pollution and iron pollution, making the crushed product purer. This is undoubtedly an important advantage for industries that need to strictly control product quality.

Optimised design to improve production efficiency

The CV228 impact crusher has been designed with a number of optimisations, such as adopting the impact crushing method of low-speed multi-chamber crushing, optimising the rotor speed and the structure of the crushing chamber, etc. These optimisations make the machine more efficient in the production process. These optimisation measures enable the equipment to maintain high efficiency and stable operation during the production process, thus improving the production efficiency.

Wide range of applications

With its excellent performance and many technical advantages, CV228 impact crusher has been widely used in many industries, such as mining, construction, chemical industry, renewable resources, water conservancy and so on. Whether in the field of stone processing, ore crushing or artificial sand production, this equipment can play an excellent role.

Strong adaptability, can handle a variety of materials

The CV228 impact crusher has wide adaptability and can handle many types of materials, including hard and brittle materials, medium-hard materials and super-hard materials. Whether it is metal ores, non-metallic ores, cement, refractory materials or glass raw materials, this equipment can easily cope with them. This wide adaptability makes CV228 impact crusher widely used in many industries.

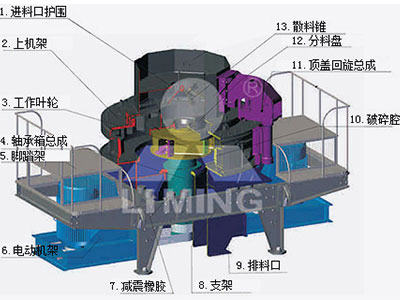

CV228 crusher is the first choice for high efficiency and low energy consumption Working Principle

The motor drives the transmission spindle of the bearing barrel to rotate at a high speed, while the rotor carries out a high-speed rotating movement. When the material enters the impeller, it will be accelerated by the impeller and ejected into the crushing cavity. In the crushing cavity, the material and the formed material lining are impacted and grinding each other, so that the kinetic energy gained from accelerating the material is converted into the energy needed for crushing or shaping. The material in the crushing chamber will go through several cycles, and under the action of the surrounding gas eddy current, it will go through the crushing and shaping process until it forms the required finished product, which will be discharged from the lower part of the machine. This kind of crushing method using mutual impact between materials is called ‘stone hitting stone’, which is mainly used for stone shaping and crushing. In addition, the machine is also equipped with ‘stone to iron’ crushing method. In this way, after the material is ejected from the rotor, it will directly hit the counter-attack block installed in the crushing chamber, and the energy gained from acceleration will be converted into the energy needed to collide with the counter-attack block for crushing. After the collision, the material will be discharged directly from the lower part of the machine body, and cannot be crushed in the crushing chamber for several cycles. Therefore, the ‘stone hitting iron’ crushing method is mainly applicable to the working occasions that require large crushing ratio.

CV228 crusher is the first choice for high efficiency and low energy consumption Technical Parameters

| feed size | 55 mm | Power | 370 kW |

| length | 4.35 m | width | 2.23 m |

| height | 3.06 m | Weight | 14,826 kg |