CI732 impact crusher fine design to meet diversified needs

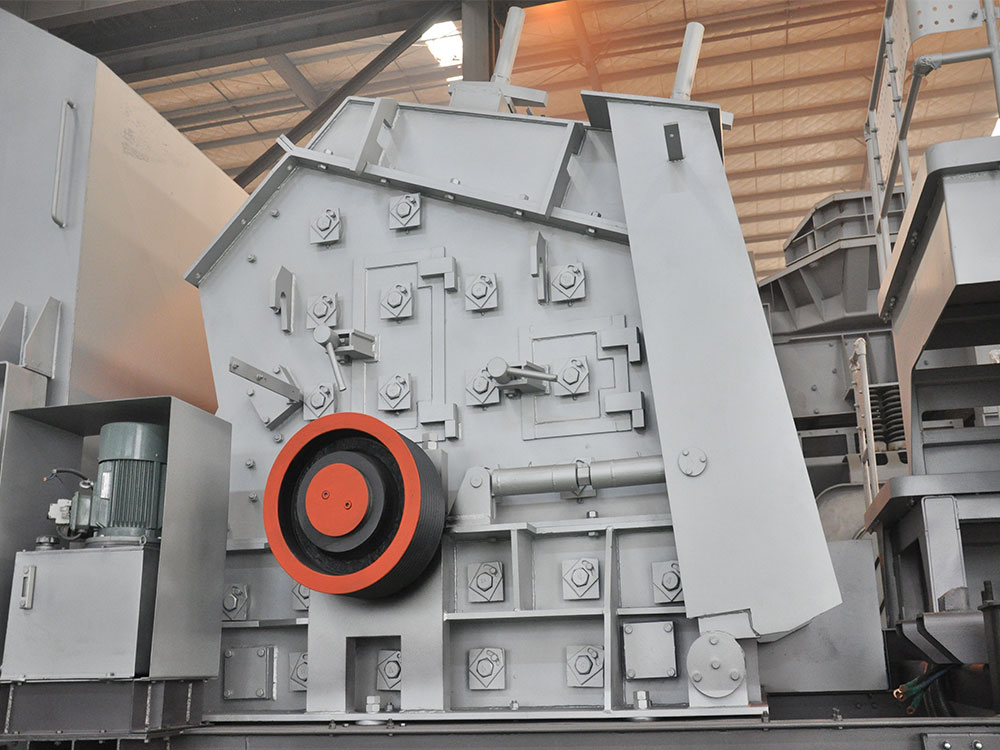

CI732 impact crusher is widely used in stone crushing operations in mining, building, road construction and other fields. Its efficient crushing capacity and stable working performance make it one of the indispensable equipment in these fields. Specifically, it can be used for crushing materials with relatively low hardness such as limestone, pyroxene, granite, etc., as well as for crushing and processing of renewable resources such as construction waste and waste concrete. Impact crusher is a kind of crushing machinery that uses impact energy to crush materials. When working, driven by the motor, the rotor rotates at a high speed, and when the material enters the plate hammer area, it is first crushed by the impact with the plate hammer on the rotor, then thrown to the impact device to be crushed again, and then bounced back to the plate hammer area to be crushed again from the impact liner. This process will be repeated, the material will enter the first, second and third impact chamber from large to small to repeat the crushing, until it is crushed to the required size, and finally discharged from the discharge port.CI732 impact crusher has a strong crushing capacity, can efficiently crush the material into the required size, improve the production efficiency. The structure of this equipment is relatively simple, easy to install and maintain, reducing the user's operating costs. The key parts such as impact plate and hammer are made of wear-resistant materials, which has a long service life and reduces the frequency of replacing parts. Users can adjust the gap between the impact plate and the plate hammer according to the actual demand, in order to adapt to the crushing demand of different particle size.

CI732 impact crusher fine design to meet diversified needs Applications

CI732 impact crusher is also widely used in metallurgical, chemical and building materials industries. In the metallurgical industry, it can be used to process materials such as ores and slag to provide suitable raw materials for the smelting process. In the chemical industry, this equipment can crush chemical raw materials and waste materials, providing the required particle size for chemical production. In the building materials industry, the CI732 Impact Crusher is able to produce high quality aggregates and sand, providing raw material support for the production of concrete, mortar and other building materials.

In the infrastructure construction of highway and railway, the quality and particle size of stone materials are extremely strict.CI732 Impact Crusher can produce excellent, stress-free cubic products to meet the high requirements of stone materials for highway and railway construction. It can crush large stone materials into the required particle size to provide high quality filler for roadbed filling and ensure the stability and safety of highways and railways. In addition, this equipment is also widely used in the crushing of railway ballast, providing high-quality ballast materials for railway construction.

With the acceleration of urbanisation, the disposal of construction waste has become an urgent problem, and the application of CI732 impact crusher in the construction field provides an effective solution for the disposal of construction waste. It is capable of crushing materials such as construction waste and waste concrete into recycled aggregates, which can be used to produce new construction materials and realise the recycling of resources. This not only reduces the pollution of construction waste to the environment, but also lowers the cost of construction materials and promotes the sustainable development of the construction industry.

In the process of mining, CI732 impact crusher is widely used in the crushing treatment of ores with its high efficiency and stable crushing performance. It is capable of crushing large ores into smaller sizes, which is convenient for subsequent processes such as ore dressing and smelting. At the same time, the equipment can also handle ores containing impurities, improve the utilisation rate of ores, and bring higher economic benefits for mining enterprises.

CI732 impact crusher fine design to meet diversified needs Advantages

High efficient crushing performance

CI732 Impact Crusher adopts advanced crushing technology and design concepts, with high efficient crushing performance. With its large crushing ratio and high crushing efficiency, it can quickly crush materials to the required size and improve production efficiency. At the same time, the equipment can also handle materials containing impurities, reduce downtime and improve equipment utilisation.

High quality product size

The products produced by CI732 Impact Crusher have even particle size and excellent shape, mostly cubic particles. This particle size is more in line with the market demand, and can improve the added value of the product. At the same time, high quality product size can also reduce the difficulty and cost of subsequent processing procedures, and improve the overall production efficiency.

Energy saving and environmental protection

CI732 Impact Crusher is designed to focus on energy saving and environmental protection. It adopts advanced crushing cavity and rotor structure to reduce energy consumption, noise and dust pollution. In addition, the equipment is capable of handling materials containing moisture, effectively preventing clogging in the crushing process and reducing energy consumption and maintenance costs.

Strong adaptability

The CI732 impact crusher has strong adaptability and can handle materials of various hardness and particle size. Whether it is medium hardness rock or materials containing impurities, this equipment can easily cope with it. This wide adaptability makes the CI732 Impact Crusher applicable in many industries to meet the needs of different customers.

Easy to maintain and service

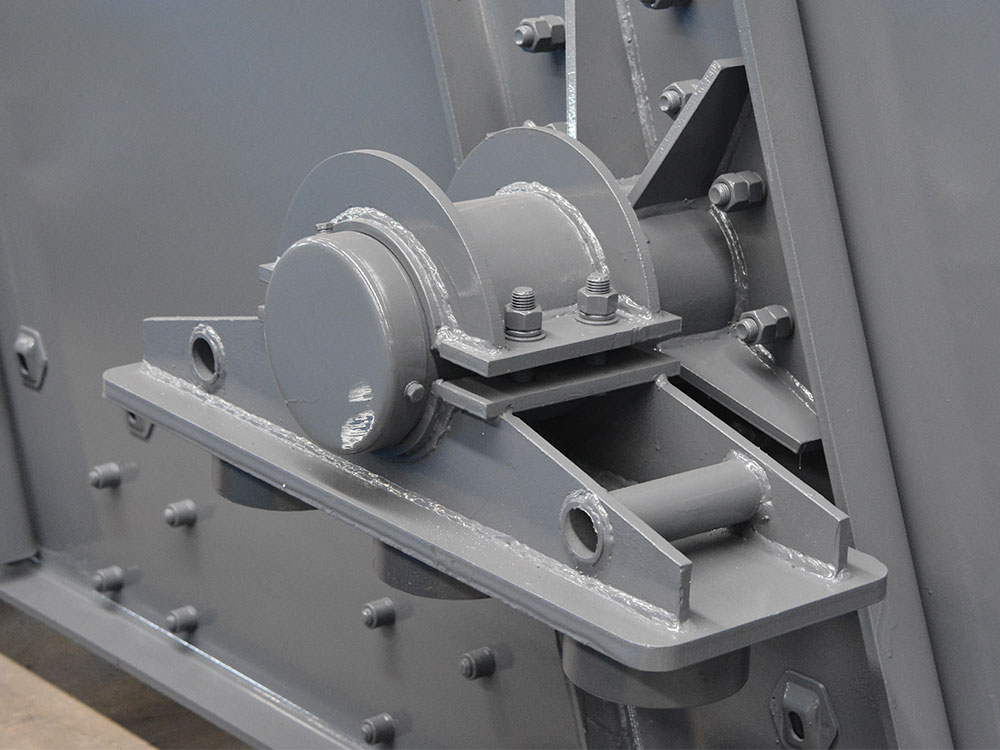

CI732 Impact Crusher adopts advanced technology such as keyless connection, which makes the maintenance and upkeep of the equipment more convenient. Users can replace and repair the equipment in a timely manner according to its operating status and wear and tear to ensure the long-term stable operation of the equipment. In addition, the equipment is equipped with a variety of safety locking devices to improve the safety performance of the equipment and reduce the risk of operation.

Intelligent control

CI732 Impact Crusher is equipped with advanced intelligent control system, which can realise automatic operation and remote monitoring of the equipment. Users can monitor the operation status and crushing effect of the equipment in real time through the control system, and adjust the working parameters in time to ensure the best operation status of the equipment. This intelligent control not only improves the production efficiency and product quality, but also reduces the labour cost and operation difficulty.

CI732 impact crusher fine design to meet diversified needs Working Principle

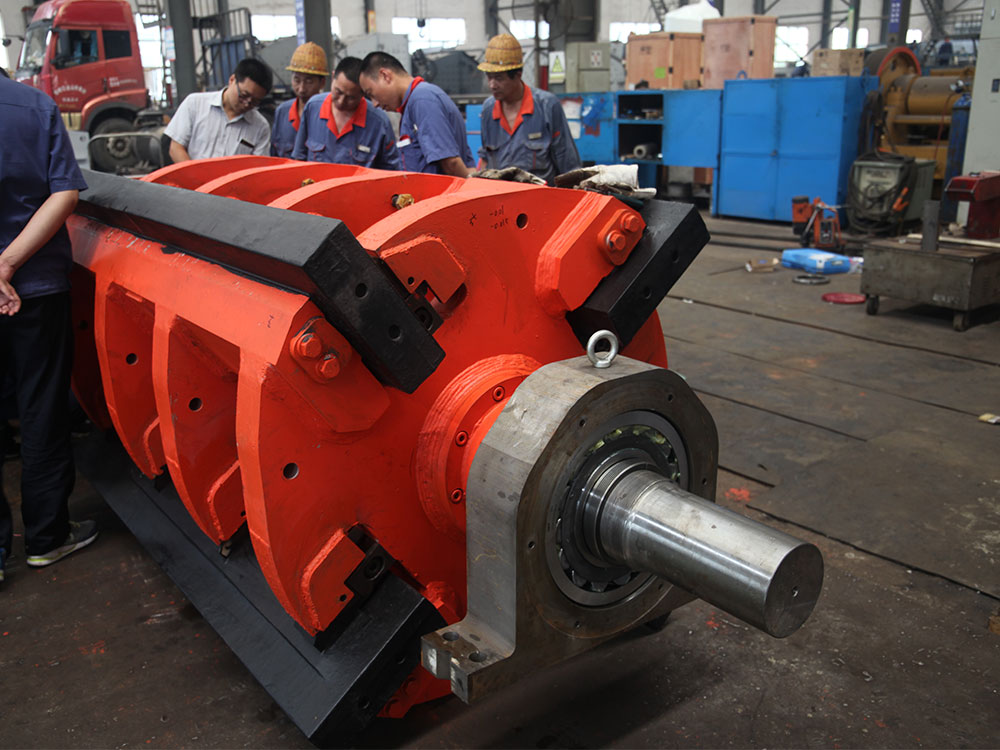

When the material enters the crusher from the feeder, it will immediately enter the rotating area of the plate hammer which is closely connected with the rotor. Here, the material will firstly be subjected to the strong impact of the high-speed rotor hammer, which has a huge impact force and can quickly cause the material to be broken for the first time. Subsequently, the first crushed material will be thrown to the impact plate on the machine body along the tangential direction at a fast rate. After hitting the impact plate, the material blocks will be subjected to a strong rebound force, which will make the material again and the rotor hammer or other material blocks have a violent impact, so as to achieve the further crushing of the material. This process is not one-time, but repeated and continuous in the crushing chamber. The materials are continuously impacted, rebounded and hit between the hammers and the impact plates, and this continuous crushing effect makes the internal organisation of the materials gradually damaged, loosened and finally broken into smaller particles. When the material is crushed to less than the gap between the impact plate and the hammer, it will be discharged from the discharge port in the lower part of the crushing chamber. At this time, the material has reached the required particle size requirements, and becomes the crushed product, which can be further used in the subsequent production or processing.

CI732 impact crusher fine design to meet diversified needs Technical Parameters

| feed size | 350 mm | power | 440 kW |

| Length | 4.07 m | width | 3.22 m |

| height | 2.84 m | Weight | 29,650 kg |