CH660 Cone Crusher Rugged and Durable Crushing Preferred

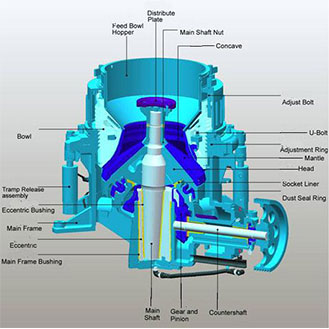

The CH660 cone crusher is designed for crushing ores, slag and other hard materials, with high crushing ratio, considerable output, low energy consumption and many other advantages. Its compact structure and delicate design are sufficient to cope with the harsh working conditions and ensure the stable operation of the equipment. The crusher mainly consists of core components such as cone head, cone seat, adjusting mechanism, lubrication system and motor. The cone head, as the key component of the crushing operation, is equipped with rotatable hammers for impact crushing of materials. The Cone Holder plays the role of supporting the cone head and transmitting the crushing force. The adjusting mechanism can flexibly adjust the rotating height and speed of the cone head to meet the needs of different materials. The lubrication system is responsible for providing the necessary lubrication to prolong the service life of the machine. The motor is the power source to drive the machine, and the working principle of CH660 Cone Crusher is to crush the material by the impact of the hammer head on the cone. When the hammer head contacts with the material, with the help of the hammer head's rotation and the rising angle effect, the material is crushed by the impact and thrown out along the tangent direction of the cone surface, and finally achieves the ideal crushing effect. The crusher is suitable for crushing ores, rocks and other hard materials, and is widely used in mining, building materials, highway and other industrial fields.

CH660 Cone Crusher Rugged and Durable Crushing Preferred Applications

CH660 cone crusher has been widely used and praised in many industries for its remarkable advantages of high efficiency, energy saving, durability and environmental protection. In the mining industry, this crusher, with its powerful crushing capacity, can easily handle ores, rocks and other materials of various hardnesses, which fully meets the high standard demand for crushing equipment in mining and mineral processing plants. Its durable design, flexible eccentricity adjustment function and stable feed opening design enable the machine to easily cope with all kinds of crushing challenges, thus improving production efficiency and product quality.

The CH660 Cone Crusher has also demonstrated its outstanding performance in the building materials field. Building materials production has a huge demand for sand and gravel aggregates, and this crusher can efficiently crush all kinds of raw materials to the required size, providing a high-quality source of raw materials for building materials production. At the same time, its small footprint and efficient output performance also makes the equipment more flexible in the layout of the building materials plant, effectively improving the overall operating efficiency of the production line.

Not only that, CH660 cone crusher also plays an indispensable role in the field of highway and other infrastructure construction. Highway construction is inseparable from a large amount of stable and reliable sand and gravel aggregates, and this crusher can efficiently crush all kinds of raw materials to meet the required particle size, which provides a strong guarantee for the smooth progress of highway construction.

CH660 Cone Crusher Rugged and Durable Crushing Preferred Advantages

Advanced lubrication system and safety device

CH660 Cone Crusher is equipped with a perfect lubrication system, which can ensure that the equipment maintains stable performance during long-time operation. When the temperature is too high or the flow rate is slow, the lubrication system will automatically shut down to prevent equipment damage. In addition, the machine is equipped with a large-throughput, high-pressure interconnection insurance hydraulic system, which provides additional safety for the machine. These advanced designs enable the CH660 Cone Crusher to maintain stable and reliable operation under harsh working conditions.

Remarkable energy saving and environmental performance

The CH660 Cone Crusher is able to make full use of the kinetic and potential energy of the material during the crushing process, achieving efficient energy conversion. At the same time, the equipment adopts a thin oil lubrication system design, which reduces the number of oil-water mixing failures and improves the life cycle and energy saving effect of the equipment. In addition, the equipment is also designed and manufactured with full consideration of environmental protection factors, adopting advanced environmental protection technology and materials, reducing noise and dust emissions, and making a positive contribution to the protection of the environment.

Strong adaptability and flexibility

CH660 Cone Crusher is extremely adaptable and capable of handling materials of various hardness and nature, such as ores, rocks, metals, plastics and so on. By adjusting the rotating height and speed of the cone head, the equipment can easily adapt to different crushing requirements, making production more flexible and versatile. In addition, its compact structural design also allows the equipment to work efficiently in a small space, improving the utilisation rate of the workplace.

Highly efficient and accurate crushing capacity

The CH660 Cone Crusher adopts advanced crushing technology, which impacts and crushes materials through the rotatable hammers on the cone head. This type of crushing is not only highly efficient, but also ensures that the crushed materials have uniform particle size to meet various industrial demands. Meanwhile, its tip part can generate stable vector force to achieve precise control and operation of the working surface, which further improves the working efficiency and quality.

CH660 Cone Crusher Rugged and Durable Crushing Preferred Working Principle

CH660 Cone Crusher is mainly composed of cone head, cone seat, adjustment device, lubrication system, motor and other parts. The cone head is the main working part of crushing, on which rotatable hammer heads are installed, which crush the materials by impact. The cone seat is used to support the cone head and transmit the crushing force. When the motor is started, it drives the transmission shaft to rotate, and then the cone head is forced by the eccentric sleeve to rotate around a fixed point. During the working process, the hammer head on the cone head continuously rotates and comes into contact with the material. Due to the rotation of the hammer head and the effect of the rising angle, the material is impacted and crushed, and thrown out along the tangent direction of the cone surface. At the same time, the cone part of the cone crusher, driven by the eccentric sleeve, makes the crushing wall of the crushing cone approach and leave the surface of the crushing wall which is fixed on the adjusting sleeve. This movement of approaching and leaving makes the ore in the crushing chamber constantly subjected to impact, extrusion and bending, so as to realise the crushing of the ore.CH660 Cone Crusher is also equipped with an adjusting device, which can regulate the rotating height and rotating speed of the cone head to adapt to the crushing requirements of different materials. The lubrication system is used to lubricate the equipment to prolong its service life. When unbreakable objects such as metal pieces fall into the crusher, the spring safety system will produce compression and deformation to discharge the foreign objects, thus preventing the machine from being damaged.

CH660 Cone Crusher Rugged and Durable Crushing Preferred Technical Parameters

| feed size | 321 mm | Weight | 29,335 kg |

| power | 315 kW | capacity | 330 t/h |

| Eccentric throw range | 18 - 50 mm | Lubrication tank | Standard |